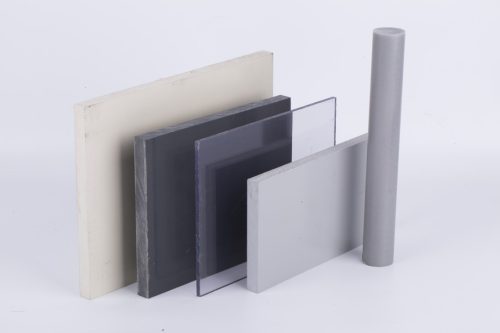

Acetal sheet is a versatile and durable plastic material that is widely used in a variety of industrial and manufacturing applications. Made from a thermoplastic polymer known as polyoxymethylene (POM), this material is known for its excellent strength, stiffness, and dimensional stability.

Features:

- High strength and stiffness

- Excellent dimensional stability

- Low moisture absorption

- Good chemical resistance

- Low friction and wear properties

- Easy to machine and fabricate

Potential Applications:

- Automotive and transportation parts

- Food and beverage processing equipment

- Medical and dental devices

- Electrical and electronic components

- Industrial machinery and equipment

- Consumer goods and appliances

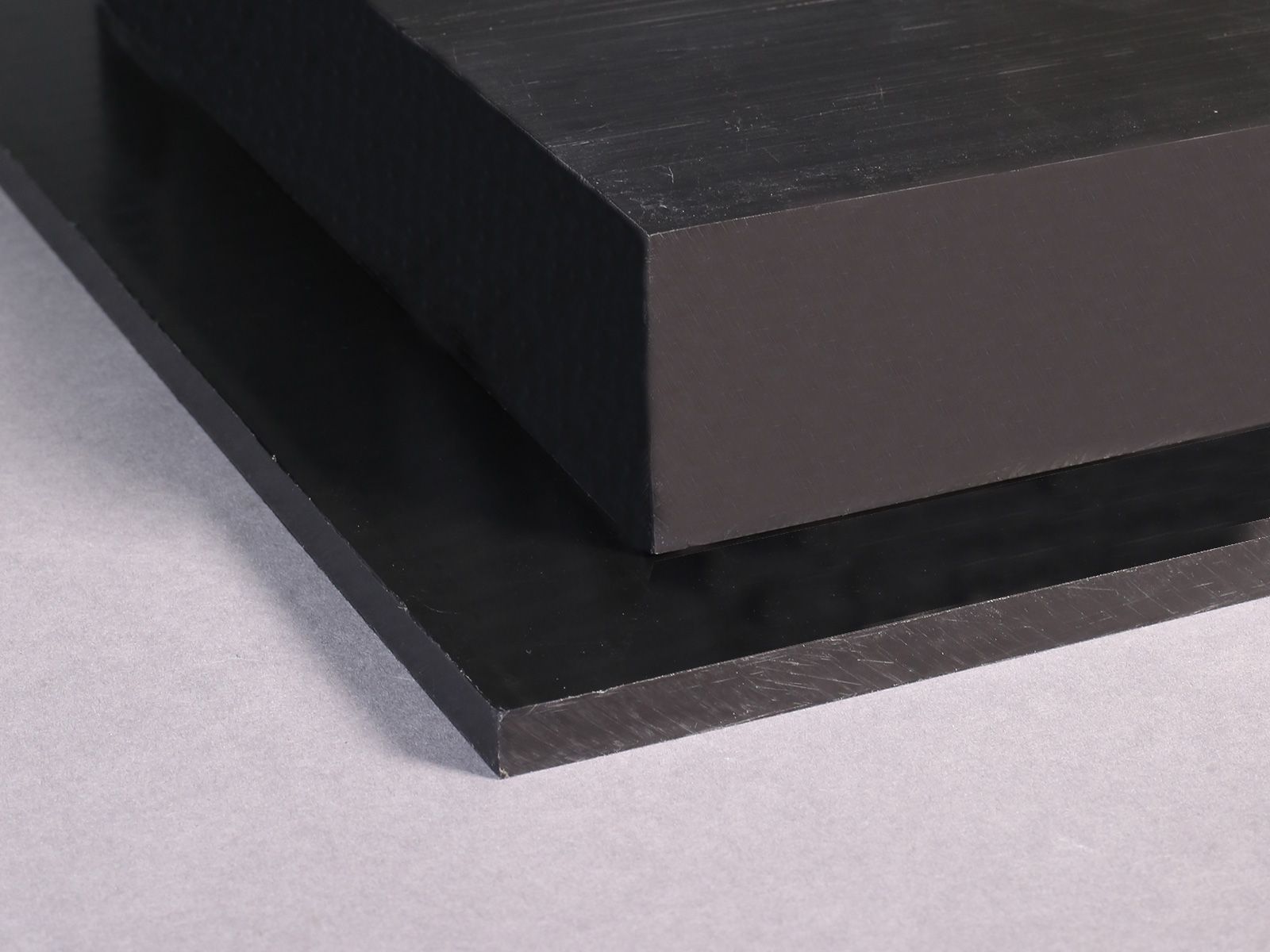

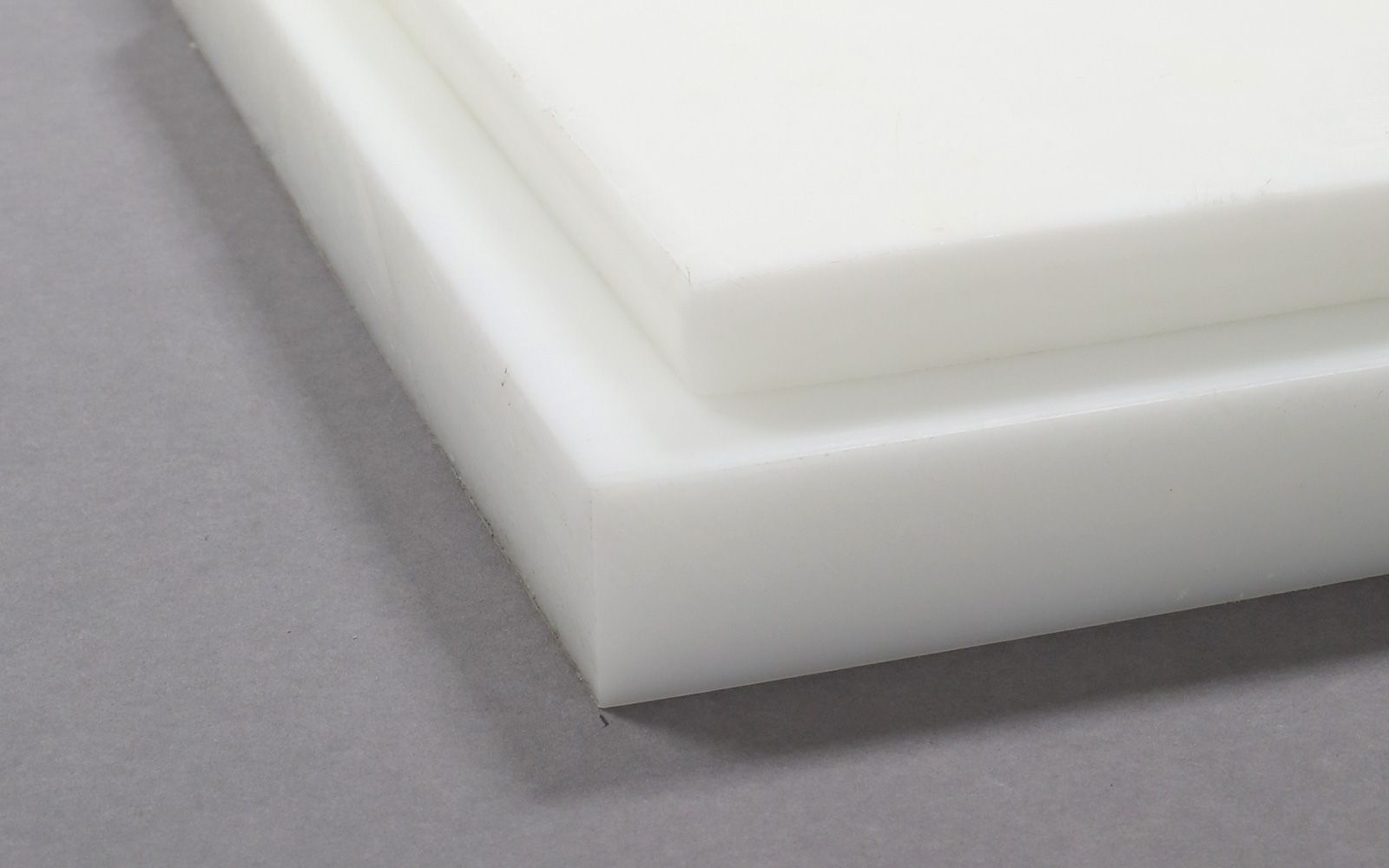

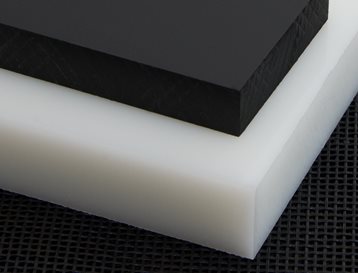

Available Colours:

- Natural

- Black

- Other colours available on request

The high strength and stiffness of acetal sheet make it an ideal choice for applications that require precise dimensional tolerances and good mechanical properties. Additionally, the material has low friction and wear properties, making it ideal for applications where sliding or moving parts are involved.

It is also very easy to machine and fabricate, making it a popular choice for a wide range of industrial and manufacturing applications.

FAQ

Q: Is Acetal the same as Delrin?

A: Yes, Delrin is a brand name for a type of Acetal polyoxymethylene (POM) plastic. It is also made from POM. Delrin® is an acetal homopolymer and has a uniform backbone with a larger crystalline block structure than acetal copolymers. More information can be found here.

Q: Is acetal plastic strong?

A: It is known for its high strength and stiffness, making it suitable for applications that require precise dimensional tolerances and good mechanical properties.

Q: Can Acetal Sheet be used in high temperature applications?

A: The use in high temperature applications is limited, as it has a relatively low melting point around 177 °C and is not suitable for prolonged exposure to temperatures above this limit.

Q: Can Acetal Sheet be used outdoors?

A: It is resistant to sunlight and weathering, making it suitable for some outdoor applications. However, it should not be used in applications that will expose it to UV light, as it is not UV stabilized and may become brittle over time.

Q: Can Acetal Sheet be welded?

A: It is difficult to weld and not recommended. Alternative joining methods such as mechanical fastening or solvent bonding can be used.

Q: Can Acetal Sheet be painted?

A: It can be painted, but it needs to be roughened first and a special primer must be used. It is also important to use a paint that is compatible with the material.