Description

Nylon sheets are a versatile and durable plastic material that is perfect for a wide range of applications. With its high strength-to-weight ratio and excellent resistance to abrasion, impact, and chemicals, it is an ideal choice for industrial and commercial use.

Features:

- High strength-to-weight ratio

- Excellent resistance to abrasion, impact, and chemicals

- Low coefficient of friction

- Good wear resistance

- High temperature resistance

- Low moisture absorption

- Easy to machine and fabricate

Potential Applications:

- Gears, bearings, and other mechanical components

- Conveyor and power transmission parts

- Wear strips, guides, and wear plates

- Bushings, Cam Disks and Mixer blades

- Chain and sprockets

- Wear resistant parts for the automotive industry

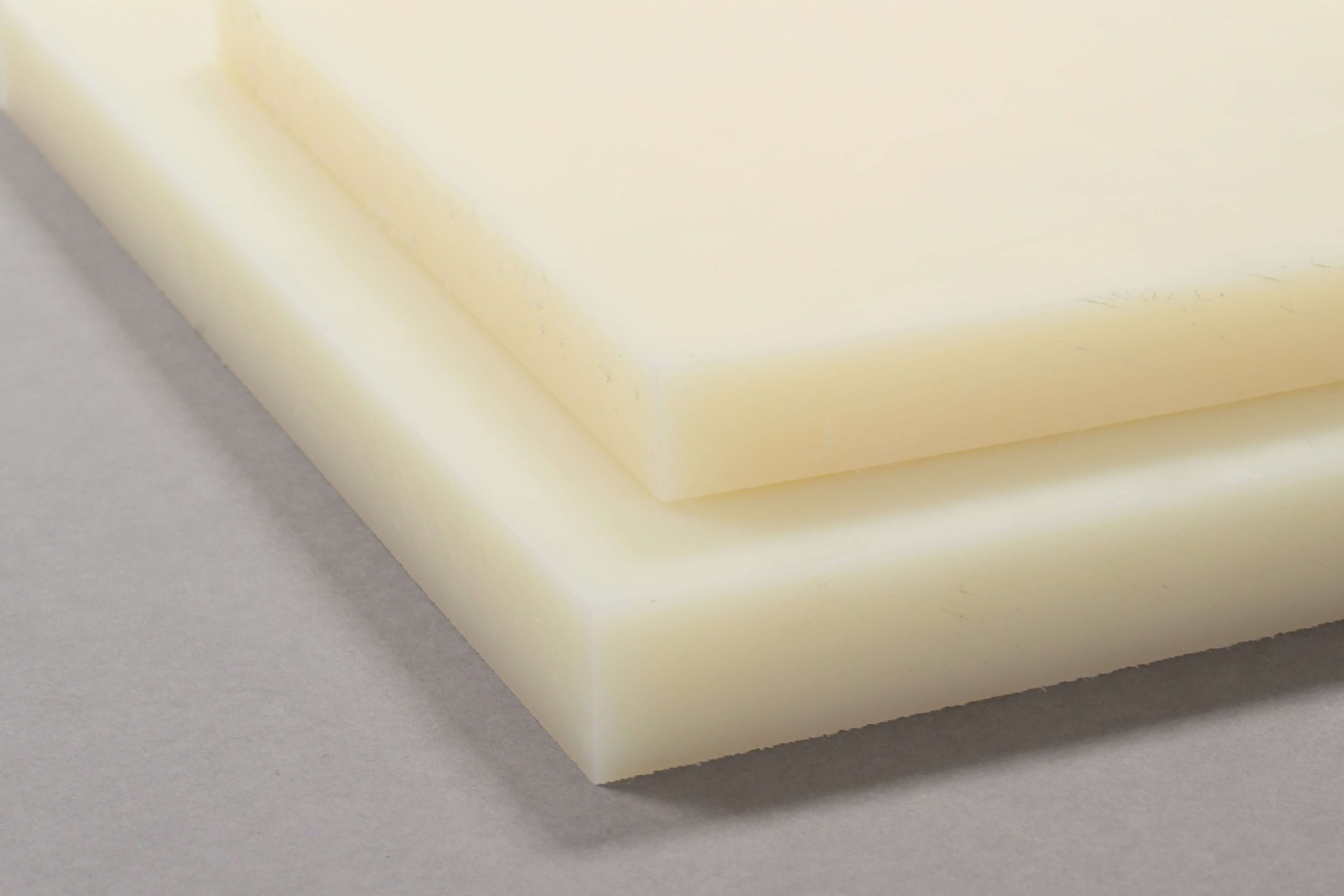

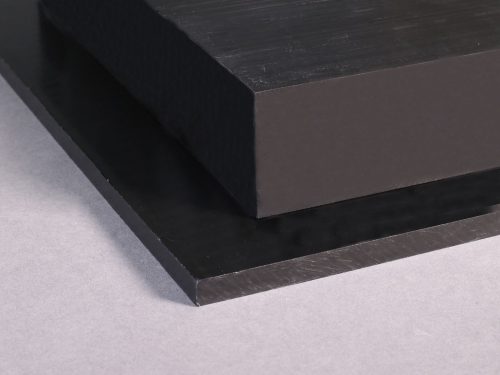

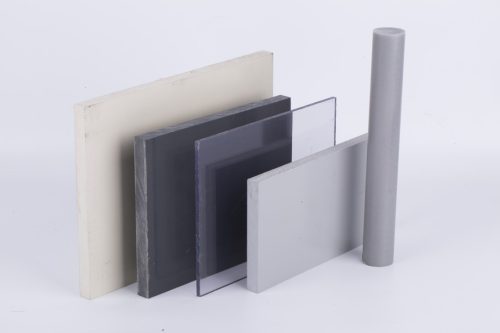

Available Colours:

- Black

- Gray

- Natural (White)

- Custom colours available upon request

FAQ:

Q: What is nylon plastic used for?

A: It is commonly used for gears, bearings, and other mechanical components, conveyor and power transmission parts, wear strips, guides, and wear plates, chain and sprockets, and wear resistant parts for the automotive industry.

Q: Is nylon stronger than plastic?

A: Nylon is known for its high strength-to-weight ratio, making it stronger than many other types of plastic.

Q: Is nylon a good plastic?

A: It a very good material, known for its high strength, excellent resistance to abrasion, impact, and chemicals, low coefficient of friction, good wear resistance, high temperature resistance, low moisture absorption, and ease of machining and fabrication.

Q: Who makes nylon?

A: It a synthetic polymer that is produced by a number of different manufacturers. DuPont is one of the most well-known manufacturers.

Q: Are they any alternatives to nylon?

A: Nylon and polypropylene are commonly used in industrial and commercial applications. It is known for its high strength-to-weight ratio and excellent resistance to abrasion, impact, and chemicals, while polypropylene is known for its chemical resistance and low cost. Nylon is more durable and stronger than polypropylene but is also more expensive. On the other hand, polypropylene is lightweight, flexible, and has a low melting point making it ideal for certain applications where weight and cost are crucial.