Laser cutting technology has completely transformed material processing with its speed and precision. As the technology evolves, it continues to open new doors across many industries. In this article, we’ll explore recent advancements, practical applications, and why choosing the right laser cutting provider can significantly impact your results.

Introduction to Laser Cutting Technology

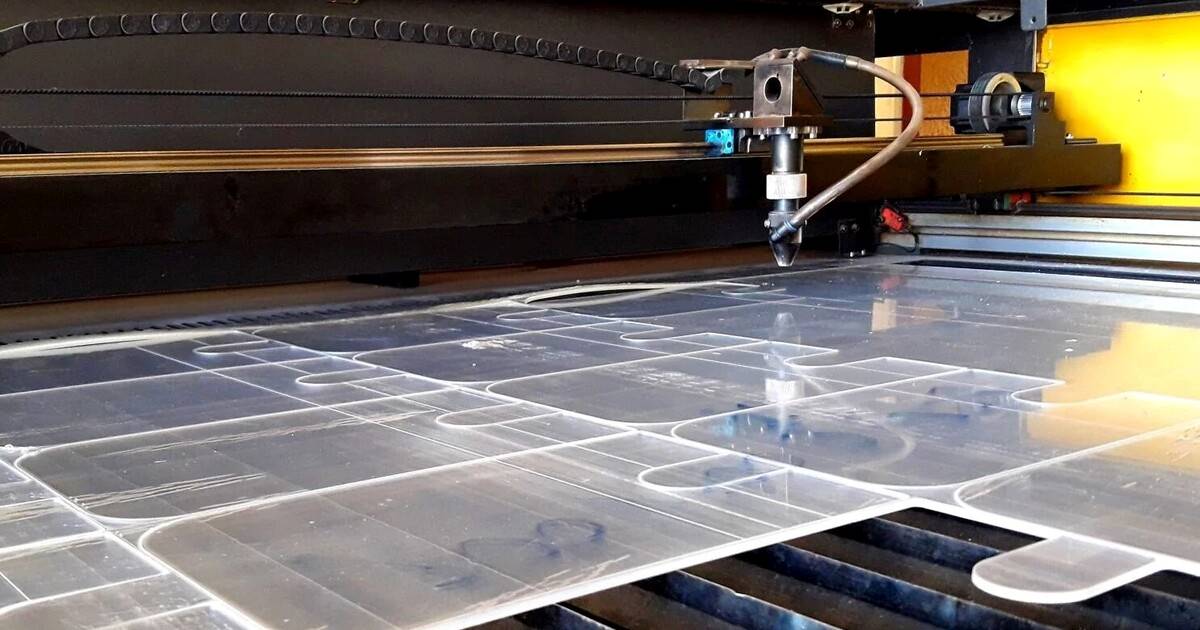

Laser cutting uses high-powered beams to cut through various materials with extreme accuracy. Over time, this technology has advanced from simple designs to highly sophisticated systems that cater to modern manufacturing needs. Today’s laser cutting systems are not only faster and more precise but are also capable of handling an expanded variety of materials.

Innovations in Laser Cutting

Recent developments in laser cutting technology have led to several significant improvements:

- Increased Speed and Precision: Modern laser cutters now deliver faster cutting times and greater accuracy, thanks to advances in laser beams and computer control systems. This results in shorter lead times and superior quality output

- Enhanced Materials Compatibility: Laser cutting systems can now work with a wider range of materials, from metals and plastics to composites, allowing for more diverse applications.

- Automation and Integration: With increasing automation and seamless integration with robotics and CAD software, laser cutting processes are becoming more efficient, reducing labor costs while speeding up production.

- Eco-Friendly Options: Newer machines consume less energy and produce minimal waste, making them more environmentally friendly than earlier models.

Types of Laser Cutting Systems

Laser cutting technology primarily operates through three types of lasers, each with unique capabilities and specific applications:

- CO2 Lasers: Known for their versatility, CO2 lasers are ideal for cutting non-metal materials like acrylic, wood, and textiles. They excel in applications where intricate designs and detailed cuts are essential, such as signage and product displays.

- Fiber Lasers: Designed for metal cutting, fiber lasers are highly energy-efficient and offer faster cutting speeds than CO2 lasers. These systems are widely used in industries that require metal fabrication, such as shopfitting and manufacturing.

- Diode Lasers: Compact and energy-efficient, diode lasers are often used for engraving or cutting thin materials like wood or plastic. While they’re less powerful than fiber or CO2 lasers, diode lasers are suitable for low-power tasks such as surface marking.

Applications of Laser Cutting Across Industries

Laser cutting’s versatility allows it to serve a wide range of industries, including:

- Automotive Industry: Precision cutting of vehicle components, including body panels and small parts, contributes to improved performance and safety.

- Aerospace Sector: High-precision cutting is crucial for aerospace components, where laser technology ensures the accuracy and reliability needed for critical applications.

- Architecture and Design: Architects and designers can create intricate, customised pieces that offer both aesthetic and functional value.

- Consumer Goods: Laser cutting plays a role in producing personalised goods, such as jewellry and custom gifts, with exceptional detail and precision

- Signage: Laser cutting provides sharp, clean edges for signage, enabling the creation of visually appealing and durable signs for both indoor and outdoor use.

- Product Display: Laser cutting is ideal for creating customized product displays and promotional materials that stand out and attract attention in retail settings.

- Shopfitting: In shopfitting, laser cutting allows for the precise and efficient production of shelving, fixtures, and other store elements, enhancing both functionality and aesthetics.

The Downsides of Inexpensive Laser Cutting Machines

While affordable laser cutting machines might seem like a good option, they come with limitations that can impact your project:

- Ongoing Maintenance: Budget machines often require more upkeep, leading to higher long-term costs and increased downtime.

- Lack of Support: Inexpensive machines typically offer minimal customer support, making it difficult to resolve issues efficiently.

- Material Wastage: These machines may require larger sheets of material to be cut down to size, resulting in unnecessary wastage. In contrast, a professional service provider will use only the amount of material required for each project, saving leftover materials for other uses and charging only for what is actually used.

Benefits of Choosing Professional Laser Cutting Services

Opting for a professional laser cutting service offers several advantages that can outweigh the benefits of using a cheaper machine:

- Cost-Effectiveness: Though the upfront cost of professional services may be higher, the reduced material waste and precision ultimately result in lower overall costs.

- Customisation: Professional providers can handle complex designs and offer high levels of customisation, delivering results that meet your specific needs.

- Efficiency: With access to advanced technology and experienced operators, professional services ensure faster turnaround times and higher production volumes.

- Material Optimisation: A good supplier will carefully plan each cut to minimize waste, saving you money and ensuring that leftover materials are efficiently used for other projects.

How to Choose a Laser Cutting Service Provider

Selecting the right laser cutting service provider is essential for achieving the best results:

- Technology and Equipment: Ensure the provider uses the latest technology and high-quality equipment to meet your project needs.

- Experience and Expertise: Look for a provider with a proven track record and expertise in handling projects similar to yours.

- Customer Service: Choose a provider that offers excellent customer support and is willing to collaborate closely with you throughout the project.

- Reputation: Check reviews and testimonials to gauge the reliability and quality of the provider’s services.

Laser cutting technology continues to push the boundaries of what’s possible, making it a vital tool across numerous industries. By keeping up with advancements and partnering with a reputable service provider, you can make the most of laser cutting for your projects, ensuring precision, efficiency, and quality.

Looking to enhance your next project with cutting-edge laser technology? Get in touch today to learn more about our laser cutting services.